- 易迪拓培训,专注于微波、射频、天线设计工程师的培养

如何对锂离子电池进行高效率的充电(一)

How to Charge a Li-Ion Battery

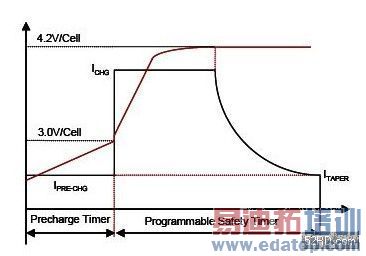

Figure 1 shows a popular charge profile recommended for a Li-Ion battery. Most dedicated Li-Ion-charge integrated circuits (ICs) are designed to charge the battery in this manner. The charging of a Li-Ion battery consists of three phases: pre-charge; fast-charge constant current (CC); and constant voltage (CV) termination. In the pre-charge phase, the battery is charged at a low-rate (typical of 1/10 the fast charge rate) when the battery cell voltage is below 3.0 V. This provides recovery of the passivating layer which might be dissolved after prolonged storage in deep discharge state. It also prevents overheating at 1C charge when partial copper decomposition appears on anode-shorted cells on over-discharge. When the battery cell voltage reaches 3.0 V, the charger enters to the CC phase.

Fast-charge current should be limited to 1C rate (0.7°C rate) to prevent overheating and resulting accelerated degradation. However, cells designed for high power capability can allow higher charge rates. Rates should be selected so that the battery temperature does not exceed 50°C at the end of charge. The battery is charged at the fast-charge rate until the battery reaches a voltage regulation limit (typical of 4.2 V/cell, but 4.1 V for coke-based anodes Li-Ion battery). The charger starts to regulate the battery voltage and enters CV phase while the charge current exponentially drops to a defined termination level. However, the output voltage regulation accuracy is critical to maximizing battery capacity and improving its service life. Less battery voltage regulation accuracy means to undercharge the battery, which results in a large decrease in battery capacity. The battery loses about eight percent capacity if it is undercharged by one percent voltage. On the other hand, less battery voltage regulation accuracy also means the battery is overcharged, which reduces the battery service life-cycle. To safely charge the Li-Ion battery, it only allows initiating to charge the battery when the ambient temperature is between 0°C to 45°C. Charging the battery at lower temperatures promotes formation of metallic Lithium, which increases the battery impedance and causes cell degradation. On the other hand, charging the battery at higher temperatures causes accelerated degradation because of promoting Li-electrolyte reaction. This presents a market need for more accurate, efficient and safe battery charge for portable devices.