- 易迪拓培训,专注于微波、射频、天线设计工程师的培养

OnSemiNCP1631300WSLIMLCDTV电源解决方案

录入:edatop.com 点击:

LCD TV电源参考设计考卷和方框图,电路图与材料清单.

The NCP1631 integrates a dual MOSFET driver for interleaved PFC applications. Interleaving consists of paralleling two small stages in lieu of a bigger one, more difficult to design. This approach has several merits like the ease of implementation, the use of smaller components or a better distribution of the heating.

Also, Interleaving extends the power range of Critical Conduction Mode that is an efficient and cost effective technique (no need for low trr diodes). In addition, the NCP1631 drivers are 180 phase shift for a significantly reduced current ripple.

Housed in a SOIC16 package, the circuit incorporates all the features necessary for building robust and compact interleaved PFC stages, with a minimum of external components.

NCP1631主要特性:

Near Unity Power Factor

Substantial 180 Phase Shift in All Conditions Including Transient Phases

Frequency Clamped Critical Conduction Mode (FCCrM)i.e.Fixed Frequency, Discontinuous Conduction Mode Operation with Critical Conduction Achievable in Most Stressful Conditions

FCCrM Operation Optimizes the PFC Stage Efficiency Over the Load Range

Out of phase Control for Low EMI and a Reduced rms Current in the Bulk Capacitor

Frequency Fold back at Low Power to Further Improve the Light Load Efficiency

Accurate Zero Current Detection by Auxiliary Winding for Valley Turn On

Fast Line / Load Transient Compensation

High Drive Capability: 500 mA / +800 mA

Signal to Indicate that the PFC is Ready for Operation (“pfcOK” Pin)

VCC Range: from 10 V to 20 V

NCP1631安全特性:

Output Over and Under Voltage Protection

Brown Out Detection with a 50 ms Delay to Help Meet Hold up Time Specifications

Soft Start for Smooth Start up Operation

Programmable Adjustment of the Maximum Power

Over Current Limitation

Detection of Inrush Currents

NCP1631应用:

Computer Power Supplies

LCD / Plasma Flat Panels

All Off Line Appliances Requiring Power Factor Correction

图1.NCP1631功能方框图

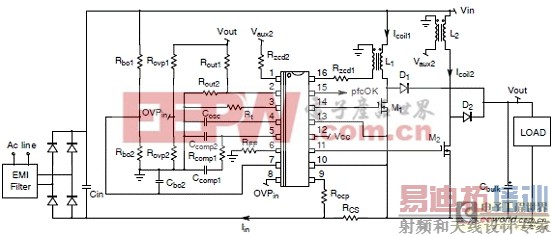

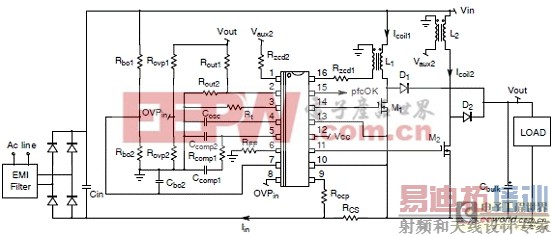

图2.NCP1631典型应用电路图

300W SLIM LCD TV电源参考设计

This reference document describes a built-and-tested, GreenPoint solution for an LCD-TV power solution that combines the main system power without a backlight power converter. In this architecture, the backlight power converter is designed on a separated board to allow full design flexibility and easier adaptation to any backlight solution and technology (Classical 24 V Hall Bridge resonance Power Supply or LIPS / High Voltage Inverter for CCFL, Power converter for Fronts or Edge LED Backlight or finally Power converter for PDP /Plasma panel).

This reference design circuit consists of a 290 mm x 310 mm printed circuit board designed to fit into the chassis of a Flat-TV. The height is limited to 8 mm to allow advanced Slim low depth LCD TV design. All the circuitry is resident in on a single-sided PCB as might be found on an LCD-TV but with FR4 / Glass Epoxy material. This allows large holes in the PCB without adding issues in drop or vibration tests.

The low profile design has a direct impact on the passive component definitions.

The overall winding parts (common mode EMI filters, PFC coils, Standby and Flyback transformers) have been defined with a low profile ferrite core and a new bobbin, allowing the parts to be lower than 8 mm with holes in the PCB included.

The large electrolytic capacitors have been split into multiple lower values and inserted flat on the board. They measure a diameter of 10 mm, and also include holes in the PCB. The heat sinks have been designed with a new low profile allowing them to be below 7 mm.

The ON Semiconductor devices utilized are from the latest generation of controllers. This design has been engineered to achieve optimum performance compared to traditional LCD-TV power architectures, while simplifying the overall bill of materials. This is done by selecting a proprietary high performance low power mode standby integrated switcher, a high efficiency interleaved Frequency Clamp Critical Conduction Mode (FCCrM) PFC, and a Flyback controller topology that provides the power to the overall TV signal processing and audio amplifiers. To provide higher design flexibility, 2 types of Flyback controllers have been considered requiring minimal changes to move from one to the other. The first one is a new Quasi Resonance (QR) mode while the second is a fixed frequency PWM.

图3.300W SLIM LCD TV电源参考设计外形图

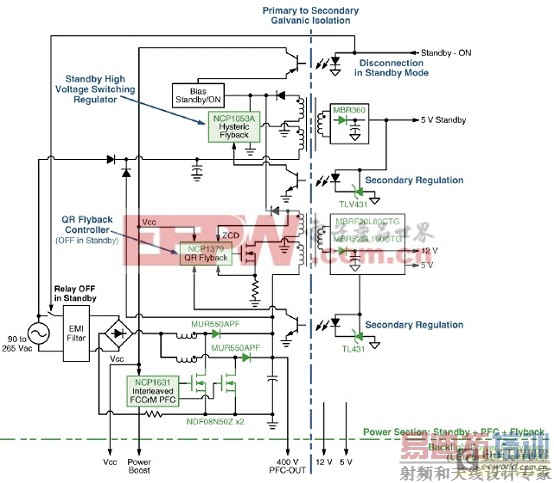

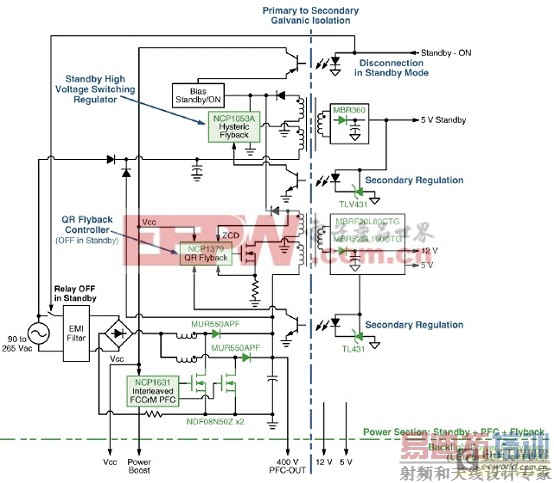

图4.300W SLIM LCD TV电源参考设计方框图

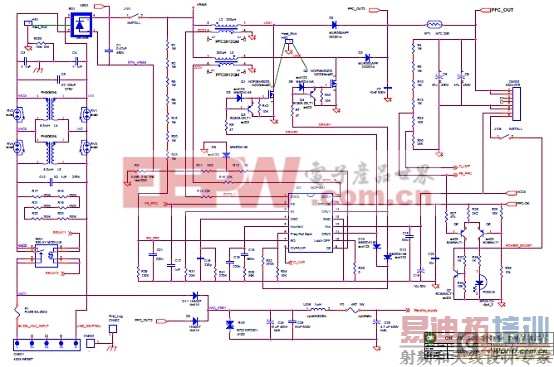

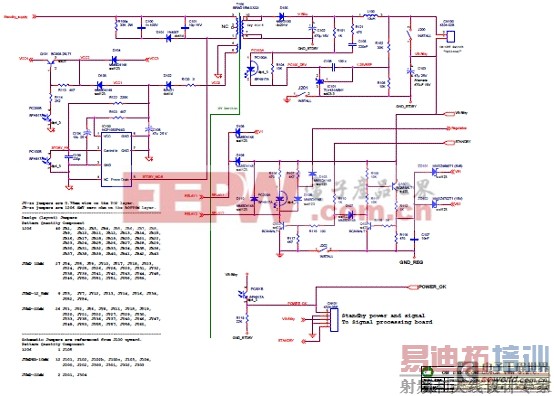

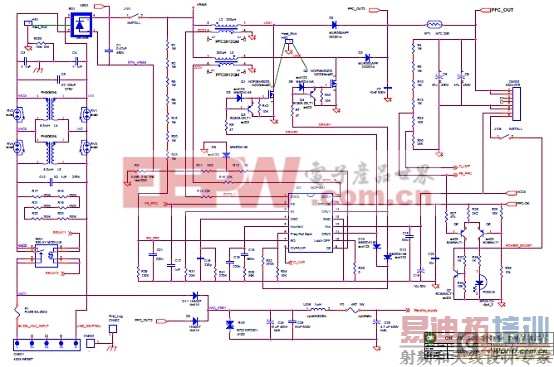

图5. 8毫米SLIM 主滤波器和PFC电路图

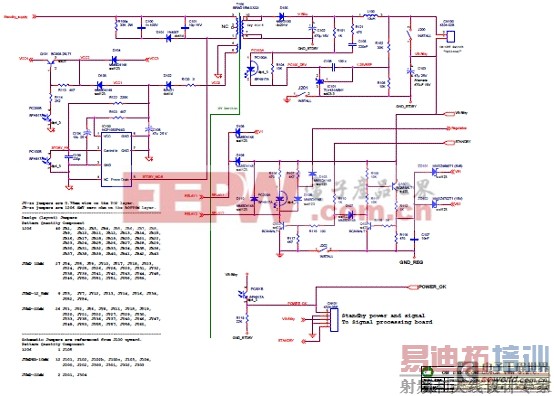

图6. 8毫米SLIM ECO待机电源电路图

图7. 8毫米SLIM QR反激电源电路图

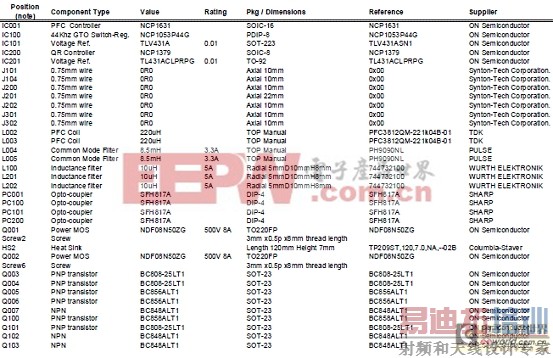

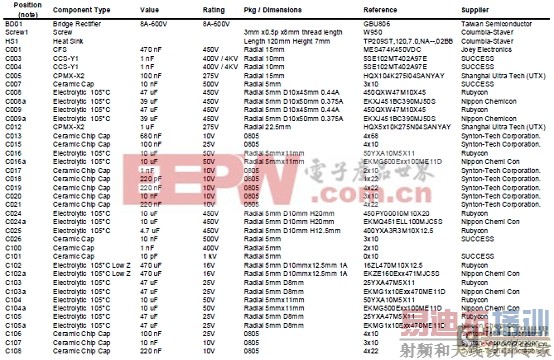

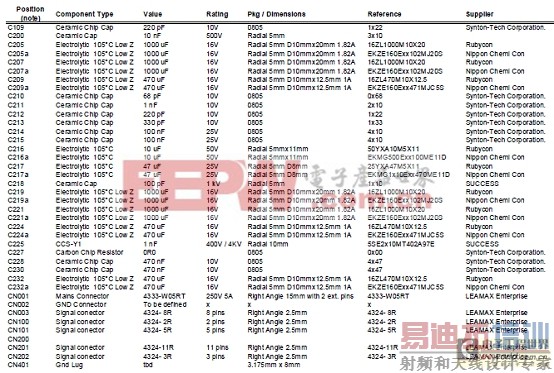

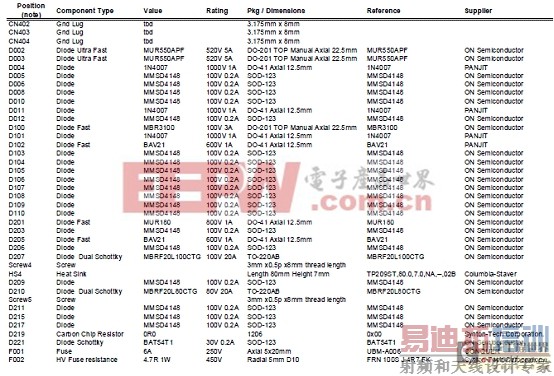

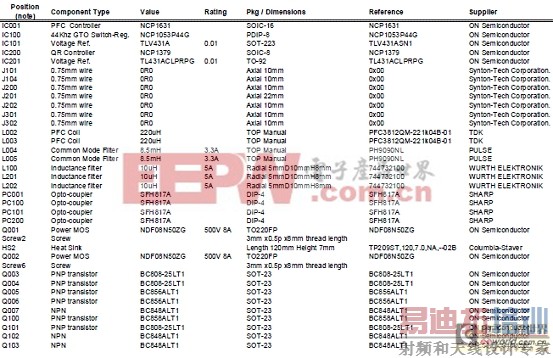

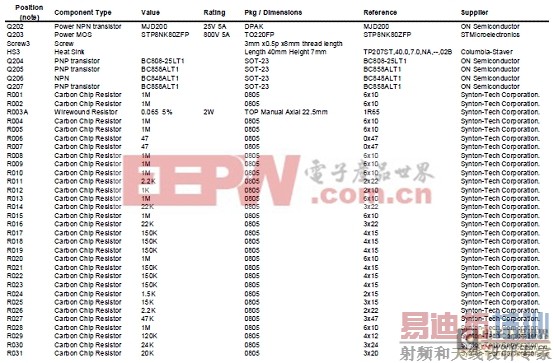

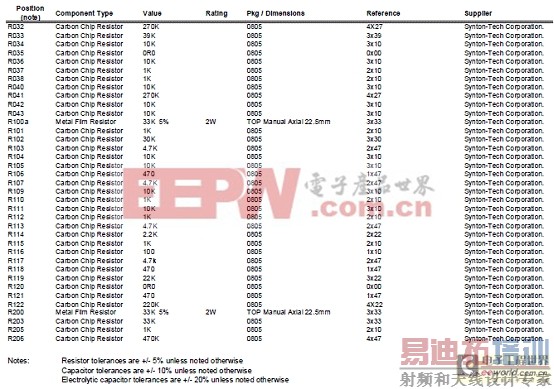

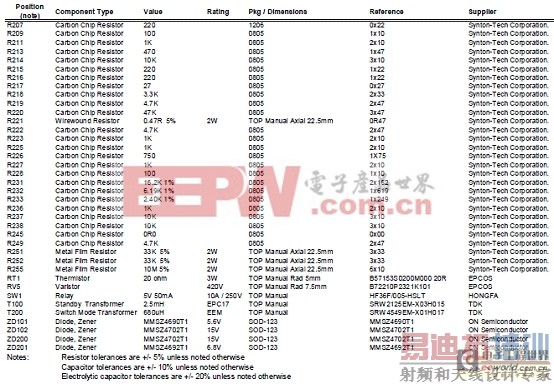

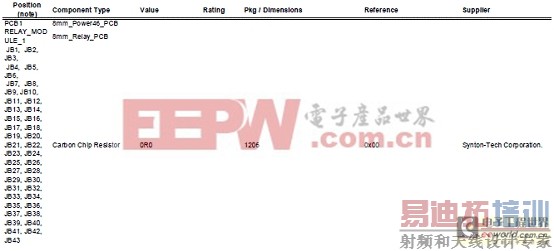

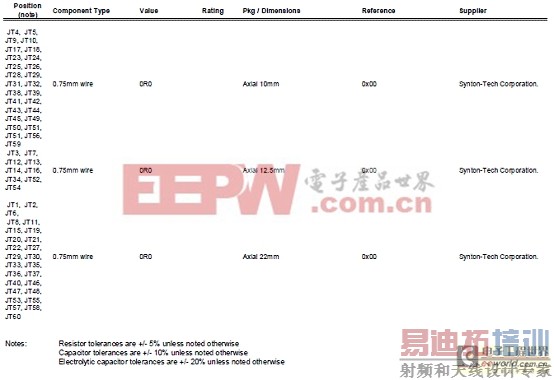

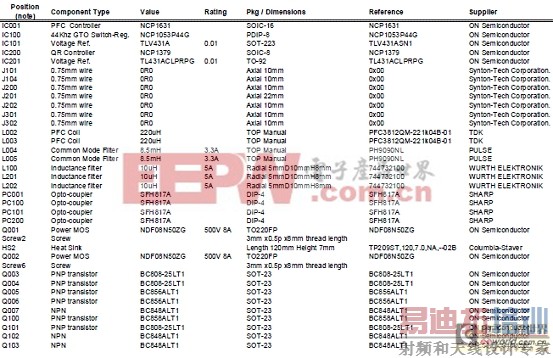

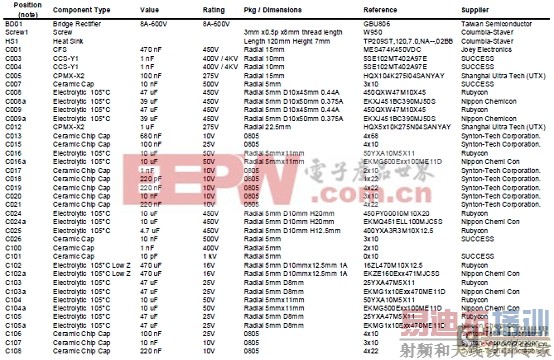

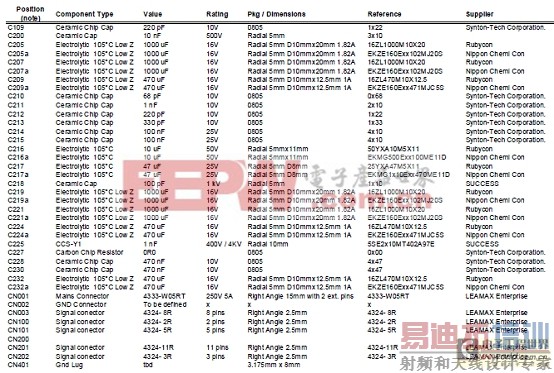

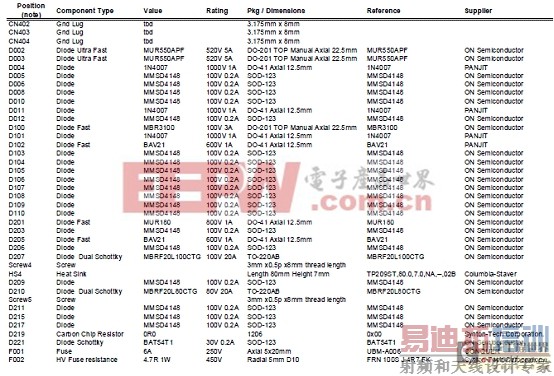

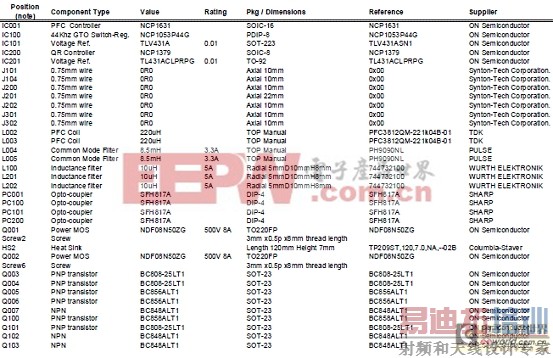

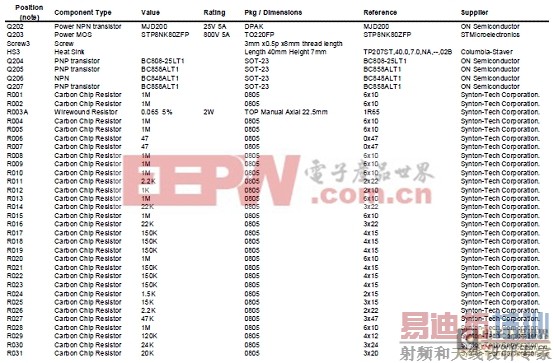

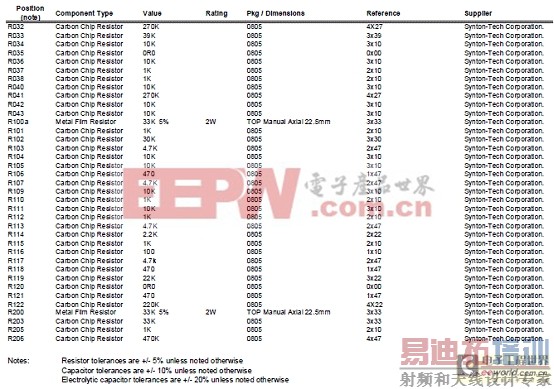

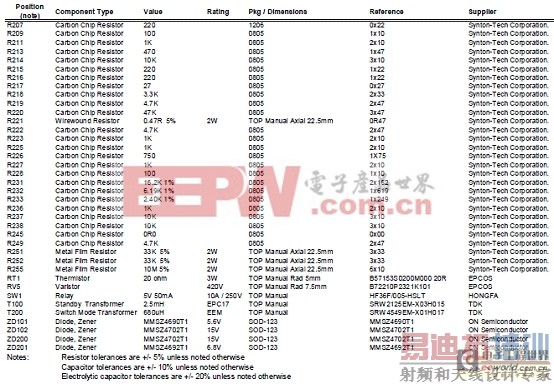

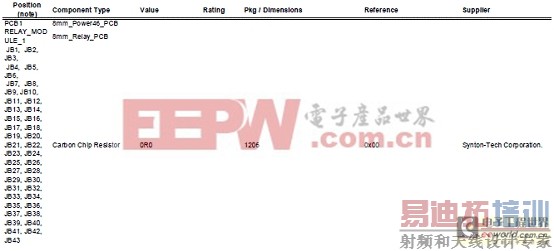

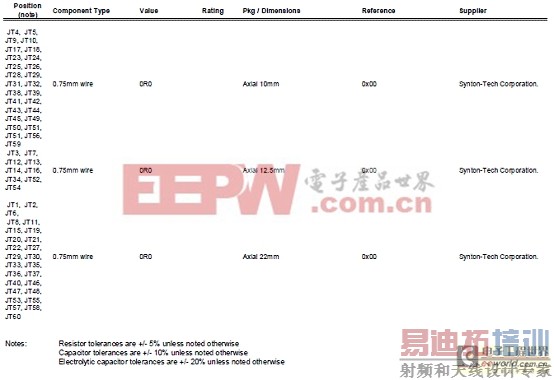

300W 8毫米LCD TV电源材料清单:

详情请见K

详情

详情请见:

http://www.onsemi.cn/pub_link/Collateral/NCP1631-D.PDF

和

http://www.onsemi.cn/pub_link/Collateral/TND401-D.PDF

The NCP1631 integrates a dual MOSFET driver for interleaved PFC applications. Interleaving consists of paralleling two small stages in lieu of a bigger one, more difficult to design. This approach has several merits like the ease of implementation, the use of smaller components or a better distribution of the heating.

Also, Interleaving extends the power range of Critical Conduction Mode that is an efficient and cost effective technique (no need for low trr diodes). In addition, the NCP1631 drivers are 180 phase shift for a significantly reduced current ripple.

Housed in a SOIC16 package, the circuit incorporates all the features necessary for building robust and compact interleaved PFC stages, with a minimum of external components.

NCP1631主要特性:

Near Unity Power Factor

Substantial 180 Phase Shift in All Conditions Including Transient Phases

Frequency Clamped Critical Conduction Mode (FCCrM)i.e.Fixed Frequency, Discontinuous Conduction Mode Operation with Critical Conduction Achievable in Most Stressful Conditions

FCCrM Operation Optimizes the PFC Stage Efficiency Over the Load Range

Out of phase Control for Low EMI and a Reduced rms Current in the Bulk Capacitor

Frequency Fold back at Low Power to Further Improve the Light Load Efficiency

Accurate Zero Current Detection by Auxiliary Winding for Valley Turn On

Fast Line / Load Transient Compensation

High Drive Capability: 500 mA / +800 mA

Signal to Indicate that the PFC is Ready for Operation (“pfcOK” Pin)

VCC Range: from 10 V to 20 V

NCP1631安全特性:

Output Over and Under Voltage Protection

Brown Out Detection with a 50 ms Delay to Help Meet Hold up Time Specifications

Soft Start for Smooth Start up Operation

Programmable Adjustment of the Maximum Power

Over Current Limitation

Detection of Inrush Currents

NCP1631应用:

Computer Power Supplies

LCD / Plasma Flat Panels

All Off Line Appliances Requiring Power Factor Correction

图1.NCP1631功能方框图

图2.NCP1631典型应用电路图

300W SLIM LCD TV电源参考设计

This reference document describes a built-and-tested, GreenPoint solution for an LCD-TV power solution that combines the main system power without a backlight power converter. In this architecture, the backlight power converter is designed on a separated board to allow full design flexibility and easier adaptation to any backlight solution and technology (Classical 24 V Hall Bridge resonance Power Supply or LIPS / High Voltage Inverter for CCFL, Power converter for Fronts or Edge LED Backlight or finally Power converter for PDP /Plasma panel).

This reference design circuit consists of a 290 mm x 310 mm printed circuit board designed to fit into the chassis of a Flat-TV. The height is limited to 8 mm to allow advanced Slim low depth LCD TV design. All the circuitry is resident in on a single-sided PCB as might be found on an LCD-TV but with FR4 / Glass Epoxy material. This allows large holes in the PCB without adding issues in drop or vibration tests.

The low profile design has a direct impact on the passive component definitions.

The overall winding parts (common mode EMI filters, PFC coils, Standby and Flyback transformers) have been defined with a low profile ferrite core and a new bobbin, allowing the parts to be lower than 8 mm with holes in the PCB included.

The large electrolytic capacitors have been split into multiple lower values and inserted flat on the board. They measure a diameter of 10 mm, and also include holes in the PCB. The heat sinks have been designed with a new low profile allowing them to be below 7 mm.

The ON Semiconductor devices utilized are from the latest generation of controllers. This design has been engineered to achieve optimum performance compared to traditional LCD-TV power architectures, while simplifying the overall bill of materials. This is done by selecting a proprietary high performance low power mode standby integrated switcher, a high efficiency interleaved Frequency Clamp Critical Conduction Mode (FCCrM) PFC, and a Flyback controller topology that provides the power to the overall TV signal processing and audio amplifiers. To provide higher design flexibility, 2 types of Flyback controllers have been considered requiring minimal changes to move from one to the other. The first one is a new Quasi Resonance (QR) mode while the second is a fixed frequency PWM.

图3.300W SLIM LCD TV电源参考设计外形图

图4.300W SLIM LCD TV电源参考设计方框图

图5. 8毫米SLIM 主滤波器和PFC电路图

图6. 8毫米SLIM ECO待机电源电路图

图7. 8毫米SLIM QR反激电源电路图

300W 8毫米LCD TV电源材料清单:

详情请见K

详情

详情请见:

http://www.onsemi.cn/pub_link/Collateral/NCP1631-D.PDF

和

http://www.onsemi.cn/pub_link/Collateral/TND401-D.PDF

射频工程师养成培训教程套装,助您快速成为一名优秀射频工程师...

天线设计工程师培训课程套装,资深专家授课,让天线设计不再难...

上一篇:安控SCADA系统在变配电监控中的应用

下一篇:锂电池生产中的机器人应用方案

射频和天线工程师培训课程详情>>